PVC Duct Hose vs PU Duct Hose: Which One Is Right for Your Industrial Ventilation Needs?

Introduction

In industrial ventilation, dust extraction, and material conveying systems, selecting the right flexible duct hose is critical to ensuring optimal system performance, safety, and maintenance efficiency. PVC (Polyvinyl Chloride) and PU (Polyurethane) duct hoses are two of the most commonly used options. This article will help you understand the key differences between these materials and guide you in choosing the best solution for your specific application.

What is a PVC Duct Hose?

PVC duct hoses are manufactured from polyvinyl chloride and are often reinforced with a steel wire helix to enhance flexibility and resistance to vacuum pressure. They are lightweight, economical, and well-suited for general-purpose ventilation and dust collection applications.

Key Features:

Economical and budget-friendly

Highly transparent wall for easy visual inspection of material flow

Flexible and easy to handle in light-duty environments

Suitable for low to moderate-duty industrial applications

What is a PU Duct Hose?

PU (Polyurethane) duct hoses are renowned for their excellent abrasion resistance, high flexibility, and extended service life. They perform exceptionally well in environments with frequent bending or abrasive materials, making them ideal for demanding industrial applications.

Key Features:

Exceptional abrasion resistance for handling abrasive materials

Excellent flexibility, even in low-temperature environments

Extended service life, reducing maintenance and replacement frequency

Ideal for heavy-duty transfer of dust, powders, and solid particles

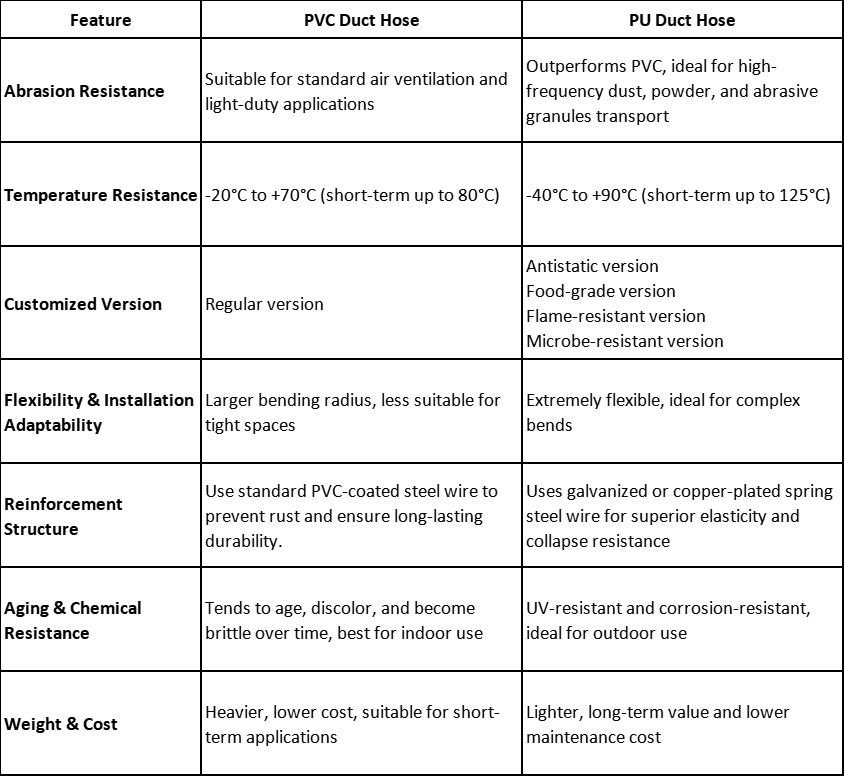

PVC Duct Hose vs PU Duct Hose Performance Comparison

Which Hose is Suitable for Your Needs?

When selecting the right duct hose, consider the following factors, which are critical for making the best choice for your specific needs:

✅ PU Duct Hose is ideal for:

Woodworking shops and furniture factories (for dust and wood chip extraction)

Conveying grain, seeds, plastic pellets, and other abrasive bulk materials

High-friction or high-flex applications with frequent bending

Cold storage facilities or outdoor ducting systems

Chemical and welding fume extraction

✅ PVC Duct Hose is best suited for:

General ventilation and air movement

Temporary or mobile dust collection setups

Short-term or budget-conscious projects

Environments with minimal abrasion and wear

Key Factors to Consider:

When deciding between PVC and PU duct hoses, keep the following in mind:

- Material being transported (dust, powder, chips, pellets, etc.)

- Frequency of bending or movement

- Operating temperature and environmental conditions

- Required durability vs. budget

💡 Tip: While PU hoses may have a higher initial cost, their durability and superior performance often result in lower long-term maintenance and replacement costs.

Why Choose Us as Your Hose Supplier?

Symboflex Technology Ltd. is a leading manufacturer of industrial ducting hoses with over 16 years of experience in producing PVC and PU hoses. We offer:

A full range of industrial ducting hoses

OEM/ODM customization (diameter, length, color, reinforcement)

Short lead times, stable quality, and competitive pricing

RoHS compliance

Expertise in serving industries such as woodworking, plastics, HVAC, ventilation, and more.

Choosing the Right Ducting Matters More Than the Price

Each duct type serves a specific purpose, and choosing the wrong one can lead to higher long-term costs.

PVC is ideal for light-duty, short-term, and budget-friendly applications, while PU offers superior durability for heavy-duty and long-term use.

Still unsure which to choose? We’re happy to help—with personalized advice and free samples available upon request.

Contact us today for expert support, a sample, or a customized quote.